Business

27 May 2024

Share

Journey around the Workbench: the Bench Peg

Have you ever considered the importance of the bench peg, that small beveled wooden surface attached to the front of the jeweler’s large workbench? It’s a real wonder.

By Sandrine Merle.

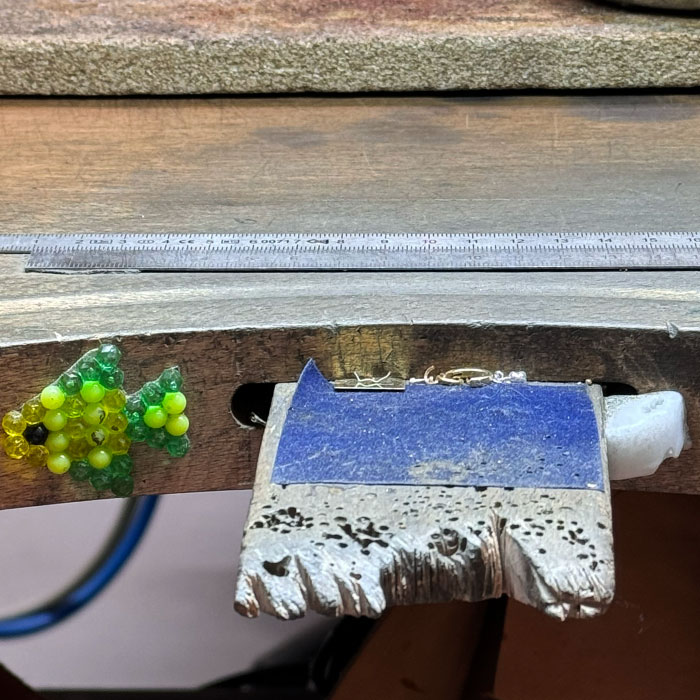

This sort of mini addition to the main workbench, the bench peg, crafted from solid beech wood, is an indispensable tool for any artisan, especially a jeweler. Beveled, it allows the jeweler to secure a piece for sawing, filing, or drilling straight and to turn it in all directions. All while being protected from slips, tremors, or vibrations that could cause the saw to break. A constant fear since the saws used are extremely fine and can quickly cause serious injury.

A Highly Personalized Tool

The bench peg is an extremely personal tool,” explains Philippe, a craftsman at the Arthus-Bertrand workshop. A bit like a pair of shoes, it can’t be lent or exchanged, because it’s made over time according to gestures, work habits, the hand or the type of piece being made.” Craftsmen use it to find their bearings, they know where to lean in to give the best of themselves. There are no two identical craftsmen in the world! All the more so since, depending on the country, its shape can vary. In the event of a change of workbench, the jeweler is ready to give up his saws and stalls, but never his bench peg. And changing when it wears out – between 5 and 10 times in a career – is always an ordeal.

An Endless Conversation Topic

You’d be amazed at the conversations, discussions and suggestions this tool generates on the Internet and in specialized forums! Every detail is important. Everything from the names of suppliers to the placement of a stop strip on the side, the type of wood, the ideal thickness and how to position it. The ideal thickness would be 2 cm, with the thinner part at the front, so that the artisan can easily place their hands underneath. Should it be fixed on the flat or beveled side? According to most French jewelers, the flat side is better for working at right angles, but there is some debate in the forums. “A Parisian craftsman explains to me: “It also enables you to place elements of a piece of jewelry while it’s being made, without them rolling, slipping or falling off. Because even if the cowhide apron is there, just below, to catch the filings, an emerald can easily chip on contact with the metal.

Length and Notch: Two Essential Details

Should the bench peg be kept as purchased or shortened by a few centimeters? The answer varies, the key thing is to find the right position and distance between it and the eyes. “This distance must be relatively small so that the work occupies the entire field of vision and maximizes the efficiency of every gesture while observing the progress of the work,” explains jeweler Michel Zim (Quebec) on a forum. If it’s too large, precision might be lacking. As for the notch, positioned more or less to the right or left, it takes the form of a V shape (not too wide) and sometimes a U shape. “The latter is preferred by the setter who rolls the handle on which his work is fixed using shellac,” notes Olivier Baroin, who worked with a bench peg for several decades.

The Value of Wear

When new, this small board is a rather underwhelming object, with no intrinsic value. But over time, it becomes pitted, scratched, scraped, burned, and chipped in places. A piece of wax might be attached. “Bench pegs are magnificent; they testify to craftsmanship and tell the story of the pieces. I love the contrast of the raw and the refined, the damaged wood and the perfectly faceted yellow gold daisies and diamonds,” explains jeweler Emmanuel Tarpin. He and other jewelers frequently use them to showcase their creations. It’s also a way of highlighting the handmade nature of their jewelry.

Banner image: Emmanuel Tarpin

Related articles:

In Japan, in the workshop of Shinji Nakaba

Jewelry workshops, the new gold mines

Anna Hu, the technical prowess of haute joaillerie Made in France